Ecovative Design: meet the start-up that’s betting big on mushrooms

Today’s plastic packaging issue needs little introduction. For many of us, Christmas came and went, leaving a shiny trail of plastic packaging in its wake. The Guardian estimates that every year, Britain’s leading supermarkets create more than 800,000 tonnes of plastic packaging waste.

But it isn’t just about fixing packaging, the plastic problem is a complex one. Our industries are geared toward manufacturing at a large scale using petroleum-based materials because they are still the cheapest and most widely available. But the tide may turn thanks to innovative companies like Ecovative, a start-up specialising in sustainable alternatives to plastic.

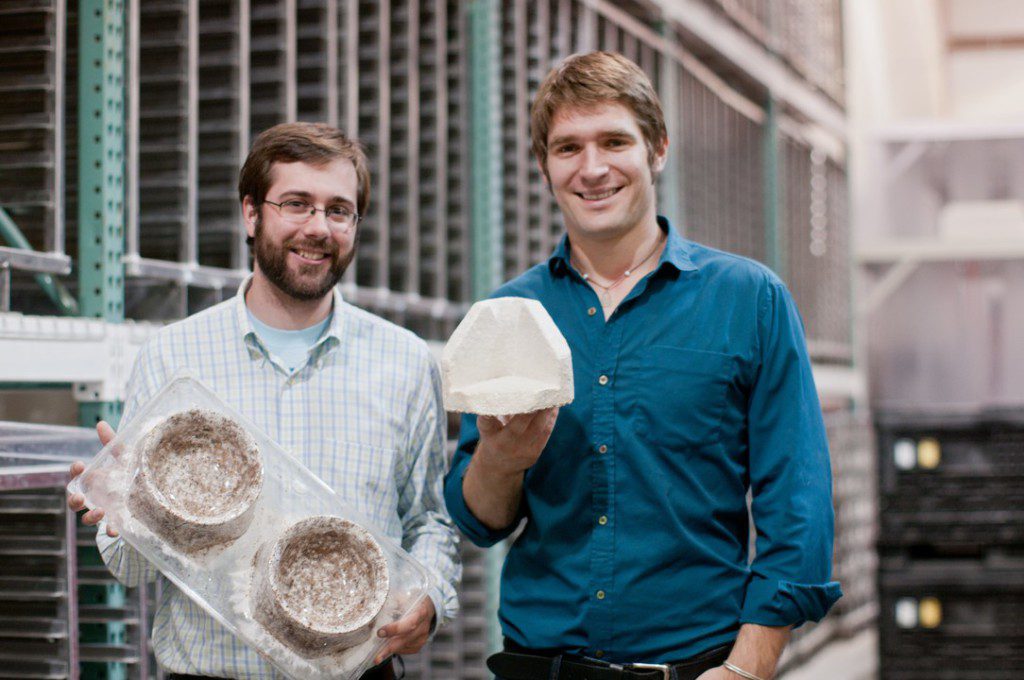

Ecovative Design founders Gavin McIntyre and Eben Bayer

Ecovative launched in 2007, when New York-based founders Eben Bayer and Gavin McIntyre began experimenting with mushrooms at university. No not that variety. While on an Inventor’s Studio course at Rensselaer, the pair developed and patented a method of growing mushroom-based insulation, initially called Greensulate. Quickly realising its potential, they, set out on a quest to “solve environmental challenges through biology”.

That quest led them to the real innovation behind Ecovative: Mycelium Biofabrication, a biological 3D printing of sorts using the root of the mushroom. By growing fungi under controlled conditions, Eben and Gavin realised they could manipulate its shape and properties, making it a highly versatile material, which the company has used to make everything from animal-free leather to IKEA’s packaging. What’s more, mycelium is biodegradable, recyclable, grows by feeding on agricultural waste and is naturally fire retardant.

“Ecovative’s new line of grown furniture fulfils the promise of a truly circular economy: every component can be returned to the earth without harm at the end of its useful life by providing nutrients, not pollutants, to the local environment”

Eben Bayer, Ecovative CEO

Growth & Success

Since the early days, Ecovative hasn’t had any trouble attracting the capital and prestige it needed to compete with the plastic manufacturing industry. In 2008, it won €500,000 from one the world’s largest sustainable innovation competitions, the PICNIC green challenge, funded by the Dutch lottery and endorsed by former-President Clinton and Sir Richard Branson no less. Deals with big consumer brands and various grants have followed.

The root of its success? Radical thinking aligned with core business sense. Ecovative’s key launch products already priced competitive with far more harmful petroleum-based plastic packaging, making the switch a no brainer for major companies like Puma and Steelcase. Investors 3M New Ventures, DOEN foundation, and the Rensselaer Polytechnic Institute have put $20.1 million (including grants) into Ecovative. In 2011, The World Economic Forum lauded the company a technology pioneer.

In 2012, Eben and Gavin’s dreams of replacing polystyrene and other petroleum-based materials were realised on an industrial scale, Ecovative penned a licensing deal with packaging behemoth, Sealed Air Corp. (market cap. $5.3 billion). There are now plans to expand into Europe. Today, the company and its products are Cradle to Cradle Gold Certified for taking-in locally produced and abundant agricultural waste, being fully compostable, and sourcing 100% renewable energy, burnishing Ecovative’s circular economy credentials.

New Arenas

“Ecovative’s new line of grown furniture fulfils the promise of a truly circular economy: every component can be returned to the earth without harm at the end of its useful life by providing nutrients, not pollutants, to the local environment,” said Ecovative CEO Eben Bayer. Just last year, Ecovative won a $9.1 million contract from the Defense Advanced Research Projects Agency (DARPA).

DARPA has had a major role in shaping technology, from groundbreaking work on the internet and prosthetics development to high-productivity computing and self driving cars. Under the DARPA project, Ecovative is tasked with developing next generation building materials. Its aim? To “spark the industries of the future, such as aerospace engineering, materials science, microelectronics and computer and information science,” said Justin Sanchez, Director of DARPA’s Biological Technologies Office.

These are all wins for Ecovative’s mushroom-based building blocks, allowing it to introduce a more versatile, more efficient and more cost effective platform into new industries. Next on Ecovative’s development agenda are sustainable apparel, beauty, food and medtech applications. We’ve heard shroom-based, lab-grown meat is in the works. Through MycoFlex, its next generation biofabrication platform, Ecovative will offer companies the ability to design, prototype and manufacture superior performance mycelium-based materials at scale.

But individuals can try out the wonder material too. Just head over to Ecovocative’s website shop. Arguably, Ecovative’s potential to help the world is vast. Estimates hint the global plastic packaging market will be worth $269.9 billion to 2025. A huge proportion of this value could be replaced with fungi-based alternatives; offering almost incalculable environmental benefits and immeasurable wealth, both financial and societal. Ecovative offers a stunning glimpse into the business and environmental potential of the circular economy. At RECONO.me, we will continue to bring you more stories on how and why circular thinking is changing the world.

Want to know more you can find Evocative Design here. Read more of our news here